News & Events

Case Study: Bond strength is key to waterproofing system performance.

Is your waterproofing system 'sticky' enough?

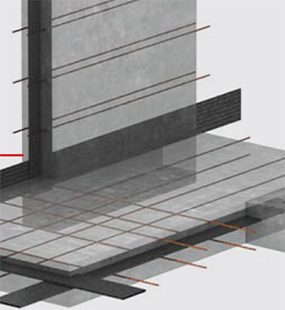

When it comes to waterproofing vital infrastructure assets – like bridge decks, one of the most important properties is bond strength. That is, how well does the waterproofing system stick to the structure and to itself? If it’s a Matacryl Waterproofing System from FPT Infrastructure, the answer is exceptionally well.

First, let’s talk about surface bond strength – how well the system sticks to the deck. Concrete and steel are the most common surfaces, however, FRP- panels – fiber reinforced polymer panels – are increasing in popularity for bridge decks and other assets like transit platforms and ramps. The bond strength to these surfaces is typically measured by Adhesion Tests ASTM D4541 (steel) and ASTM D7234 (concrete). The Matacryl System uses an MMA primer, which tests from 500 psi to over 1,000 psi routinely on steel, concrete, tile, FRP panels and other sound substrates.

Next, we’ll focus on interlayer adhesion - how well the layers of the waterproofing system stick to each other. In multilayer systems, primer, membrane, wear coats and tack coats must bond together to prevent any delamination of the system. Matacryl membranes and wear/tack coat layers are comprised of PUMA – polyurethane methyl methacrylate and MMA – methyl methacrylate. PUMA and MMA resins bond through polymerization, allowing the open polymer chains in each layer to fuse together chemically, and bond tenaciously to the substrate on which it’s applied. Other resinous systems and sheet systems rely on mechanical bond, tapes or overlay weight to keep them in place. There are hot-applied systems, like polyurea, that rely on heat rather than chemical bonding for adhesion.

A major advantage of the Matacryl system’s MMA/PUMA technology is its ability to be recoated and repaired. Over time, regular traffic can cause routine degradation of aggregate used for friction surface on wear systems. For some waterproofing systems, the entire deck down through the waterproofing system must be remove and a new system installed. With Matacryl systems, it’s possible to remove worn or spalled areas and install a new wear layer, which chemically bonds to the original system. This extends the life of the original system and mitigates the cost of full bridge deck remediation. Check out the application below to see how a Matacryl system was repaired in Yellowstone National Park.

Bond strength is the first property to consider when qualifying waterproofing systems. If it can’t stick to the deck or itself, its service life should be strongly questioned. If you doubt surface bond strength or interlayer bond capabilities of the waterproofing systems you use, Matacryl may be a better option for your applications. Contact us to start the conversation.

Application: Yellowstone National Park FRP Bridge Deck Plow Damage

In this case, an FRP panel bridge deck coated with a Matacryl Waterproofing Wear System was damaged by a snow plow with an aggressive carbide blade that scraped the system off to the depth of the panel. To recoat, the area was taped off and deck surface was cleaned with Matacryl Adcol cleaner. The clean deck was primed, and two membrane coats with aggregate were placed overlapping the existing system edge. Finally, Matacryl STC Sealer was used to seal the repair to the adjacent existing system.

Damaged Area:

Prepped and primed:

Membrane layer reinstated and sealed:

Follow us on LinkedIn

Follow us on LinkedIn Follow us on YouTube

Follow us on YouTube