Innovative waterproofing systems for bridge decks and substructures, tunnels, transit and rail platforms and aviation applications.

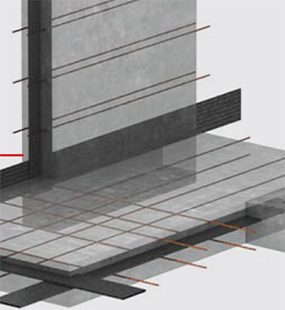

FPT Infrastructure waterproofing systems extend the service life of structures by protecting them from the ingress of water, chemicals and other contaminants that can erode or degrade concrete and steel. The workhorse layer of the system is the crack-bridging membrane. When surfaces are subject to cracking from structure movement, freeze thaw cycles and variations in substrate moisture content, the membrane flexes, expands and contracts, effectively maintaining a water-tight seal. depending on the chemistry basis of the system, membranes are rated at elongation percentages from 200 to 350%. Waterproofing systems utilize polyurethane methyl methacrylate (PUMA), methyl methacrylate (MMA), polyurethane, and polyurea chemistries.

System selection depends on a number of criteria:

- service life expectations

- substrate type

- deck capacity for overlay

- intended use and wear surface requirements

- exposure to UV over time

- expected application temperature

- environmental conditions for spray or manual application of coating

Key Advantages:

- May be applied at temperatures well below freezing (-4 F/-20 C) extending the construction season

- Exceptional interlayer adhesion strength promotes durability, even under high traffic volume use and extreme weather conditions

- Rapid set time (5-30 minutes per layer) promotes fast installation, lower labor costs and efficient handover to subsequent construction phases

- Spray and manual application grades meet environmental requirements and site conditions for equipment

- Chemically inert; does not require hazmat precautions for disposal once cured

- Customizable to the characteristics of the project by adjusting layer material and thickness, aggregate size and color, and top coat colors

Structures and Applications

- Vehicular and Rail Bridge Decks and Substructures

- Pedestrian Bike, Walking and Light Duty Bridge Decks and Substructures

- Underground and Below Grade Waterproofing for Utility, vehicular and Recreational Tunnels

- Precast and Prefabricated Components (Concrete, Steel, Fiberglass Reinforced Panels)

- Ramps, Sky Bridges, Service Garages, Plazas

- Transit Platforms, Sidewalks and Drive Lanes

- Cut and Cover (earth filled) Tunnels and Structures

Products

Matacryl WPM - under asphalt system

Matacryl PS - protective system

Matacryl WS and WS Flex - wear systems

Need more information from our Technical Consultants? Please fill out the form found here.