News & Events

Case Study: Innovative 'active' waterstops install fast and better protect foundations.

CEMflex VB Steel Blade waterstop used on future Cardiology Center foundations.

Project Details

System: CEMflex® VB

Location: Construction site of geothermal substructure of future Cardiology Center of the Montreal Heart Institute – Montreal QC Canada

Installer: Coffrage Expert for Synergy Formwork

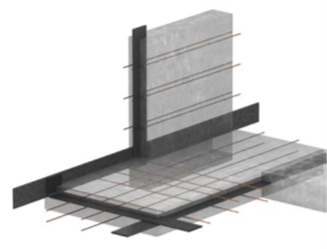

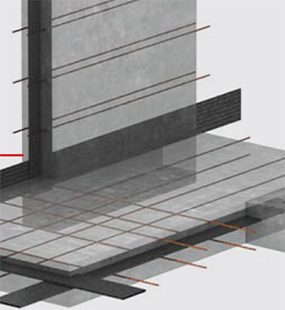

Mataproof CEMflex VB steel blade, active waterstop is an innovative approach that offers superior construction joint protection with its patented, active coating that reacts with water and moisture when embedded in concrete to seal cracks and prevent water ingress. Only 3 cm of concrete cover on both sides is necessary to seal cold joints up to 8 bar (80 m) water pressure.

FPT Infrastructure, the North American supplier of this unique solution, supplied CEMflex for substructure work on the future Cardiology Center of the Montreal Heart Institute.

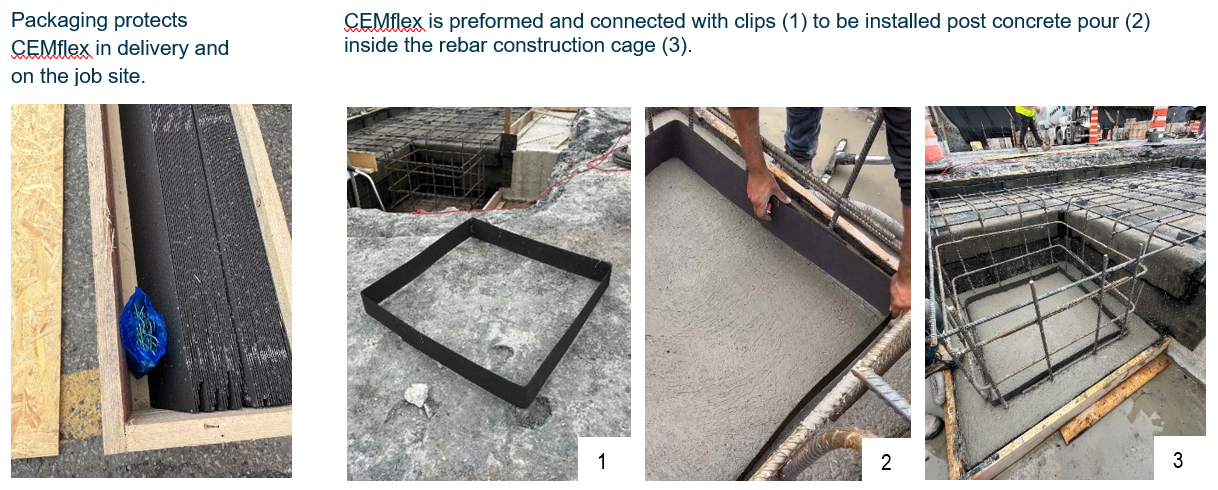

The product was accepted due to the unique active waterproofing coating, and the novel installation process including these key advantages.

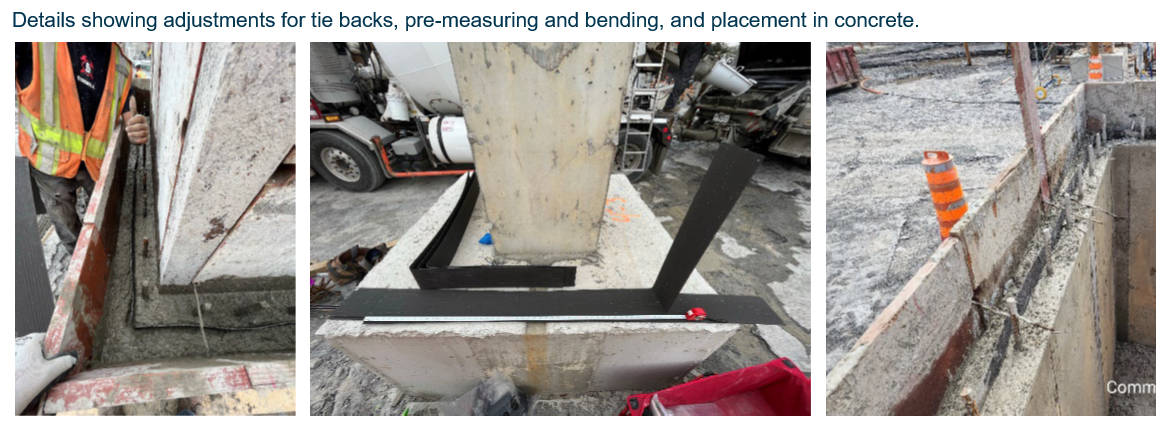

First, the product does not need to be welded like PVC waterstop, which can take from 10 to 60 minutes per corner to weld. This is a huge advantage for installers in terms of time and quality as often welds must be reworked.

Second is the advantage of positioning the material in fresh concrete or clipping in place pre-pour. CEMflex steel blades stay upright and in place in the middle of the wall, unlike PVC which can sag, ripple, and even collapse as concrete is poured over it. And PVC cannot be installed in fresh concrete like CEMflex.

CEMflex was used in horizontal cold joints in three phases of construction. A total of 40 meters was installed by a crew of 2, with total installation time of 45 to 60 minutes in the three phases. The following site images demonstrate some of the features of CEMflex and the ease of installation.

Product Details

CEMflex® VB Steel Plate Waterstop consists of a galvanized steel plate (stainless steel on special request only) encapsulated in a special patented active coating which reacts with water and moisture when embedded in concrete to provide a watertight construction joint.

The steel plate creates a physical barrier while the CEMflex active coating reacts with the alkalinity of any water in the concrete to form Calcium Hydroxide (Free Lime) which supports the natural self-healing (sintering) process of the concrete to seal cracks and eliminate water ingress. Only 3 cm of concrete cover on both sides is necessary to seal cold joints up to 8 bar (80 m water pressure).

The connection of the special coating to the concrete prevents any water-flow through the concrete construction joint.

Application

CEMflex VB Steel Plate Waterstop functions as both an active and passive barrier to the transmission of water through all non-movement construction joints (both horizontal and vertical) in in-situ reinforced concrete. It can be used in pressurized and non-pressurized water. As CEMflex is only activated by the alkalinity of fresh concrete it may be installed in all weather conditions.

Features and Benefits

- Active coating on both sides with crystallization properties, which seals cracks in the concrete

- No sticky protection tape to be removed and disposed of prior to use

- Excellent bond with concrete

- May be installed pre or post concrete pour with no collapse or displacement of the waterstop from concrete poured from above on pre-pour installations

- Welding or bonding ends is not required; simply overlap bars at least 5 cm

- Dramatically reduces installation time over PVC waterstops

- Steel is strong yet malleable so angles/corners can be formed by hand without damage to the patented CEMflex coating

- Independently tested for use up to 8 bar water pressure

- Suitable for both horizontal and vertical applications

- Fully Weatherproof System - no premature activation of the coating on contact with rainwater

- Life expectancy of 100 years

- Can be used in conjunction with other waterstop systems: PVC waterstops for movement joints, injectable hose systems or hydrophilic waterstop

Follow us on LinkedIn

Follow us on LinkedIn Follow us on YouTube

Follow us on YouTube